Introduction — why a freefall airbag attraction?

A freefall airbag attraction delivers a high-adrenaline but controlled experience: guests step off a platform and land safely on an engineered air cushion. For parks, event operators, and stunt teams, these attractions are powerful crowd magnets—if they’re designed and operated with safety and guest flow in mind. This guide explains how freefall airbags work, how to design twin-platform setups, the safety and operational requirements, maintenance, and procurement checklists so you can build a fun — and safe — attraction that scales. Throughout the article I’ll link to relevant SunparkAirbag product pages using the tag keywords as anchor text (for example: freefall airbag, amusement park, attraction setup, and airbag safety).

Table of contents

-

How freefall airbag attractions work

-

Twin-platform designs and why they’re popular

-

Key safety elements and compliance references

-

Site design and guest flow (operations)

-

Staffing, training and emergency procedures

-

Maintenance, inspection and lifecycle management

-

Sizing, footprint and installation planning (with table)

-

Cost considerations and ROI model

-

Example setups & case scenarios

-

FAQs

-

Conclusion

1. How freefall airbag attractions work

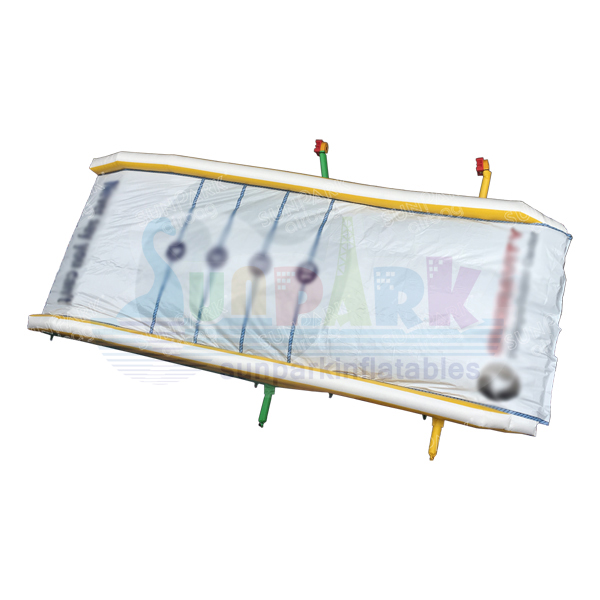

A freefall attraction uses an engineered landing surface — the freefall airbag — to decelerate a dropped person safely. Modern airbags are multi-chambered or pillar-based so impact energy is absorbed in stages, which reduces peak deceleration. Typical components:

-

Twin platforms (optional): two heights (e.g., beginner + thrill) let guests progress.

-

Enclosed landing zone: the airbag sits inside bumpers or a low wall to guide the guest and protect edges.

-

Air management system: dedicated blowers and venting let operators set firmness and re-inflate quickly.

-

Anchors and ground protection: secure the airbag against movement and wind.

Learn product options at SunparkAirbag’s Freefall Airbag category and specific models such as the Free Fall Jump Airbag product page.

2. Twin-platform designs — progressive thrills

Twin platforms are the industry-standard for attractions that need to serve first-timers and thrill-seekers on the same footprint. Typical configuration:

-

Lower platform (starter): 2–3 m height; for first-timers, reduces fear and allows staff to confirm readiness.

-

Upper platform (thrill): 3–6 m (or higher, depending on local regulation and device rating); for experienced guests or after a progression.

Why twin platforms work:

-

They increase throughput (two groups can cycle independently).

-

They help with risk management (guests build confidence on the lower platform before moving up).

-

They provide a clear programming path for events, groups, and classes.

Reference SunparkAirbag’s freefall product pages for platform compatibility and recommended heights: freefall airbag and Free Fall Jump Airbag.

3. Key safety elements & authoritative references

Safety is critical for attractions. Below are the non-negotiable elements of a safe freefall airbag installation:

Structural & equipment safety

-

Certified materials: flame-retardant, UV-stable fabrics and reinforced seams.

-

Engineered anchors: anchor maps sized for wind loads and dynamic impacts.

-

Air management: blower redundancy and vent controls to manage firmness across temperatures.

Operational safeguards

-

Controlled entry gates and marshals at the lip and landing exit.

-

Mandatory orientation and weight/health checks before each drop.

-

Progression policy: lower → higher platform only after staff sign-off.

Regulatory & standards references (external authoritative links)

Include these references in your safety pack and SOPs:

-

ASTM standards for inflatable devices and impact attenuation (search for relevant practices like ASTM F2970). See ASTM’s standards portal: https://www.astm.org/

-

European playground/attraction guidance (EN standards overview): https://en1176.org/

-

Royal Society for the Prevention of Accidents (RoSPA) guidance for attractions and public safety: https://www.rospa.com/

These sources help you build the operational paperwork needed for insurers and local authorities.

4. Site design and guest flow — operations that scale

A great freefall airbag attraction is as much about UX as it is about safety. Design considerations for smooth operation:

Approach & run-in

-

Provide a safe, non-slip walkway to the lip with clear queuing.

-

Use staged briefing areas for orientation and waivers.

Lip & jump controls

-

A secure railing and anti-slip surface at the lip.

-

Staff-controlled release (hand signal or gate) to manage single drops only.

Landing & exit

-

Clear exit route away from the landing area to avoid collisions.

-

Soft perimeter bumpers and signage.

Throughput optimization (quick math)

If each drop cycle (briefing + drop + exit) takes ~90 seconds, a single twin-platform setup with two marshals can process ~40 guests per hour during steady demand. Add a second staff member, streamline briefings with video or signage, and throughput increases. For more on air landing planning and layouts, see Air Landing overview and the SunparkAirbag Products hub.

5. Staffing, training & emergency procedures

Staffing levels, training, and clear emergency response plans are essential.

Recommended staffing

-

Lip marshal: controls release and enforces jump readiness.

-

Landing marshal: ensures clear landing area and assists guests out.

-

Supervisor/technical lead: responsible for blower systems, vents, anchors, and environmental checks.

Training topics

-

Proper briefing scripts (weight limits, posture, hands/arm positioning).

-

How to operate blowers and vents and perform daily safety checks.

-

Emergency response: retrieving a suspended or injured guest, first aid, and contacting emergency services.

Incident response

-

Keep a local emergency kit and AED nearby.

-

Log every incident with date/time, conditions and corrective actions.

-

Engage with insurer and local authority if required.

Useful staffing and safety reference: SunparkAirbag’s landing airbag and stunt airbag pages include operational notes.

6. Maintenance, inspections & lifecycle

A robust inspection regime keeps the attraction open and reduces risk.

Daily checks

-

Visual seam checks and look for abrasions.

-

Confirm blower operation and backup power.

-

Verify anchor points are intact and perimeter bumpers are secure.

Weekly & monthly

-

Clean and sanitize the shell (wipedown with approved disinfectant).

-

Filter service for blowers and full inflation pressure test.

-

Function test of vent controls and re-inflate timing.

Annual

-

Professional inspection of seams, anchors and full material assessment.

-

Replace worn components per manufacturer recommendations.

SunparkAirbag provides maintenance guidance on many product pages including the Free Fall Jump Airbag and Foam Pit Airbag.

7. Sizing, footprint & installation planning

Use the table below as a starting point for planning. Final sizing requires run-in speed testing and on-site engineering.

| Attraction Type | Typical Platform Heights | Suggested Airbag Footprint (L × W) | Recommended Cushion Depth |

|---|---|---|---|

| Family/Beginner | Lower platform 1.5–2.5 m | 6–8 m × 4–6 m | 1.0–1.5 m |

| Standard Twin Platform | Lower 2–3 m / Upper 3–5 m | 10–14 m × 6–8 m | 1.5–2.2 m |

| Large Event / High Thrill | Upper 5–8 m (regulated) | 14–20 m × 8–12 m | 2.0–3.0 m |

Notes:

-

Add extra width if multiple impact zones exist.

-

Check ground bearing capacity and drainage planning (outdoor installations).

-

Always review SunparkAirbag’s footprint and anchor drawings during procurement: Products hub.

8. Cost considerations & return on experience

CAPEX items

-

Airbag unit(s), blower(s), anchor systems, platforms, railings, signage, and power supply upgrades.

OPEX items

-

Electricity for blowers, staffing, cleaning & repair parts, and insurance premiums.

Revenue considerations

-

Ticket price per ride, throughput per hour, group/party bookings, event rentals, and seasonality.

Simple ROI sketch: with a 2-platform setup operating 8 hours/day, 50–200 guests/day (depending on park and demand), a modest per-ride price can pay back CAPEX within months to a few seasons — especially when the attraction attracts events and parties. Use SunparkAirbag’s Products hub to get quotes and accurate CAPEX figures.

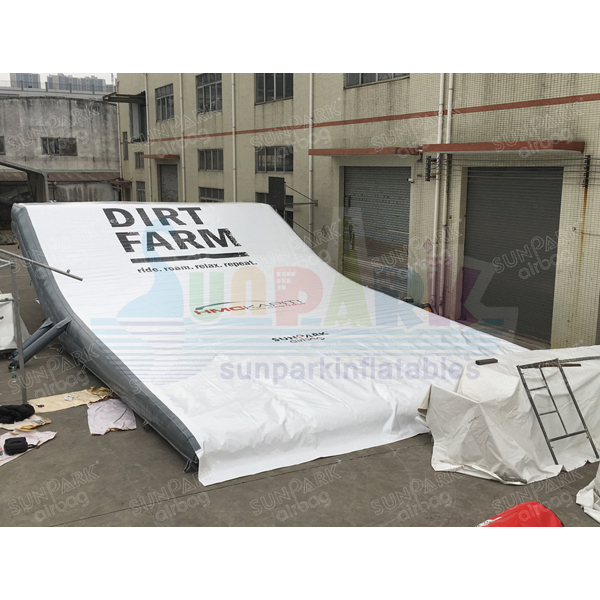

9. Example setups & case scenarios

Small park — community events

-

Twin platform (2 m / 4 m), single airbag, local power, two staff.

-

Focus: weekend events, birthday parties, school groups.

Medium theme park — permanent install

-

Permanent steel platforms, two airbags (redundancy for maintenance), integrated queueing, three-person crew per shift.

-

Focus: daily operation, seasonal peaks, corporate event rentals.

Touring festival setup

-

Quick-deploy inflatable tower and a robust freefall airbag with a trailer for transport.

-

Focus: short event windows, fast install/uninstall, and clear safety briefings for transient guests.

Examples and product ideas: Freefall Airbag category, Inflated Landing Bag (FMX), and Stunt Airbag.

10. Frequently Asked Questions (FAQs)

Q: Is a freefall airbag safe for children?

A: Yes, with properly sized lower platforms, staff briefings, and weight/health screening. Use a dedicated children’s session or lower platform only.

Q: What weather limits apply for outdoor freefall airbags?

A: Strong wind is the primary concern. Follow the manufacturer’s wind rating and add anchors for exposed sites. Have a wind-shutdown policy in SOPs.

Q: How fast does an airbag need to re-inflate?

A: Re-inflate speed depends on blower size; plan for fast re-inflation (seconds to a few minutes) and have backups for events.

Q: Do guests sign waivers?

A: Yes — waivers recommended and often required by insurers. Keep copies and an incident log for all events.

11. Conclusion

A well-designed freefall airbag attraction—especially a twin-platform setup—delivers memorable thrills while maintaining a high standard of safety and operational efficiency. By following the steps in this guide (correct sizing, engineered anchors, staff training, daily inspections, and compliance documentation) you can open a crowd-pleasing attraction that boosts park attendance and revenue.