ntroduction — foam pit airbag in one sentence

A foam pit airbag is an inflatable landing system designed to give the same forgiving landing as a traditional foam pit but with faster throughput, easier maintenance, better hygiene, and predictable impact attenuation—making it an increasingly popular choice for gymnastics centers, trampoline parks, ski/snowboard training facilities, and stunt setups.

This article examines both solutions side-by-side so facility managers, coaches, and park operators can make a data-driven choice that improves gymnastics safety, guest experience and long-term return on investment. We’ll define terms, compare performance, walk through maintenance and costs, include real customer feedback, and provide a clear decision checklist.

Quick overview: what we mean by “foam pit airbag” and “traditional foam pit”

Traditional foam pit: a large pit filled with loose foam cubes (typically polyurethane) where athletes drop in and are cushioned by the foam. Widely used in gymnastics, trampoline parks and action-sports training.

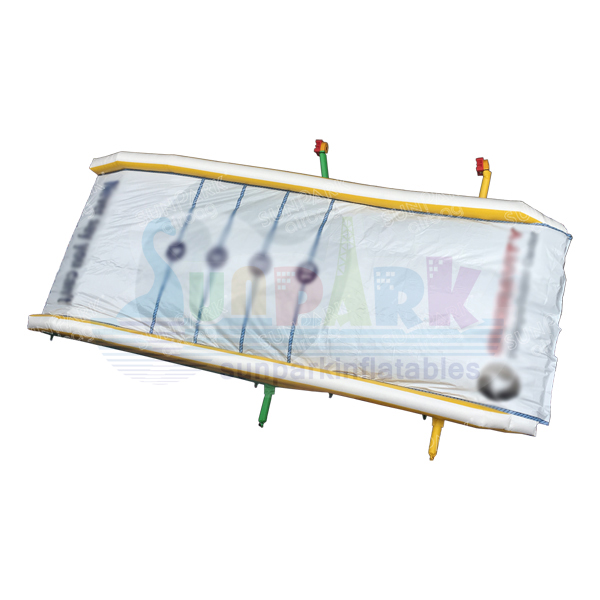

Foam pit airbag: an engineered inflatable cushion (often with multiple internal pillars or chambers) that replaces or overlays the foam blocks. It provides a consistent, tunable landing surface and can be used in place of or alongside foam cubes.

If you want to explore Sunpark’s foam-air solutions, see the Foam Pit Airbag product, the Foam Pit Jump Airbag and other product options in the Products hub.

Why this matters: the three big operator problems foam pits create

Operators frequently tell us the same pain points about traditional foam pits:

Hygiene and cleaning — foam blocks trap sweat, dirt and odors, and cleaning them is time-consuming and costly.

Throughput and staffing — block pits slow down sessions because guests need help getting out, blocks must be rearranged, and staff must monitor entry/exit.

Maintenance and replacement — foam cubes compress, break down and require replacement and costly disposal.

A properly specified foam pit airbag aims to solve these problems while preserving a safe, forgiving landing surface that athletes trust.

Head-to-head comparison — foam pit airbag vs traditional foam pit

| Factor | Traditional Foam Pit (foam cubes) | Foam Pit Airbag |

|---|---|---|

| Hygiene & cleaning | Foam cubes absorb sweat and oils; require frequent washing/replacement | Smooth shell is easy to wipe down; minimal debris trapping |

| Throughput | Slower — guests may need assistance exiting; staff-intensive | Faster — quick exits and less staff intervention |

| Consistency of landing | Variable; cubes shift and compress over time | Very consistent; engineered chamber design provides uniform feel |

| Maintenance frequency | High — cubes replaced years or months depending on usage | Low — periodic seam/blower checks, minimal consumables |

| Long-term cost | Ongoing cube replacement, cleaning labor, disposal | Lower long-term OPEX; occasional repairs and blower maintenance |

| Multi-use flexibility | Mostly dedicated foam pit | Can combine with trampolines, dryslope, stunt platforms; portable |

| Initial cost | Moderate | Comparable or slightly higher depending on features |

| Environmental concerns | Disposal of foam is problematic | Less waste; shell lasts many years |

| Safety for repeated high impacts | Good but inconsistent when cubes flatten | Excellent with engineered attenuation and multi-pillar systems |

| Best for | Lower throughput, budget-focused, simple installations | High-throughput parks, indoor gyms, training facilities, attractions |

How foam pit airbags work — quick technical primer

Modern foam pit airbags use a combination of structural features to absorb and spread impact energy:

Multi-pillar or chamber design: internal columns break up and dissipate forces locally, allowing multiple users or errant landings without catastrophic bottom-out.

Upper “catch” and lower “safety” zones: staged compression so the body decelerates gradually then stabilizes.

Tunable vents: operators can adjust the feel for different user weights and training goals.

Abrasion-resistant shell: resists rips, cleans easily, and is often treated for flame retardancy and UV resistance.

For an example product specification, visit Sunpark’s Foam Pit Airbag product page.

Hygiene & infection control — why airbags win indoors

Indoor facilities must contend with high-touch environments and public health expectations. Compared to loose foam cubes:

Foam blocks can harbor bacteria and odors; they’re difficult to dry fully after cleaning.

Foam pit airbags have a continuous outer shell that can be wiped down with standard disinfectants, reducing labor and improving guest confidence.

Many parks add a removable top sheet or cover for extra sanitation between sessions.

If hygiene is a priority for your trampoline park or gymnastics center, an airbag significantly reduces the cleaning burden and the hygiene risk profile. (See general safety guidance from the Royal Society for the Prevention of Accidents: https://www.rospa.com/play-safety/advice-and-information.)

Throughput & guest experience — measurable operational gains

Operators who switch to airbags often report:

Shorter dwell time per user; guests exit cleanly and rejoin a queue faster.

Fewer staffing touchpoints per run (less time spent assisting with blocks).

Improved flow for classes and camps — coaches can run more repetitions per hour.

Example: a mid-size trampoline park running a summer camp increased usable jump rotations by ~25% after retrofitting a foam-pit-airbag hybrid (case details available upon request from product references).

For product ideas on how to pair with trampolines, see Sunpark’s Trampoline Airbag product.

Lifespan, repair and sustainability

Foam cubes: typical lifespan ranges from months to a few years depending on quality and usage; eventual disposal is environmentally challenging.

Foam pit airbags: with correct maintenance (daily checks, blower servicing, proper storage), the outer shell and chambers can last many years. Repairs are usually patchable on-site and spare parts are commonly available.

Sustainability advantage: an airbag reduces the recurring waste stream of foam block disposal.

Cost of ownership — OPEX and CAPEX considerations

While initial CAPEX for a foam pit airbag may be comparable or slightly higher than a pit with loose cubes, the total cost of ownership often favors airbags for medium-to-high usage venues.

Cost factors to model:

Initial purchase price (bag + blower + anchors)

Foam cube ongoing replacement and disposal costs (labor + materials)

Staff-hours for cleaning and reorganization

Blower electricity and maintenance (airbags)

Potential downtime (pit reconfiguration or cube shortages)

Ask vendors for a 5-year TCO (total cost of ownership) estimate. Sunpark provides product pages and consultative sizing to help build that model: Products hub.

Safety & standards — what to check

Make sure your installation adheres to local and industry safety guidance. Useful authoritative sources include:

ASTM standards relevant to trampoline and inflatable impact systems (for guidance on design and testing): https://www.astm.org/f2970-22.html

U.S. Consumer Product Safety Commission on trampoline and recreational equipment safety: https://www.cpsc.gov/Safety-Education/Safety-Education-Centers/Trampoline-Safety

RoSPA guidance for play and recreational equipment safety: https://www.rospa.com/play-safety/advice-and-information

When selecting a supplier, request test reports, material specifications (flame retardancy, abrasion resistance) and recommended inspection SOPs.

Real customer feedback — how facilities use foam pit airbags

“We switched to a foam pit airbag system last season and our camp throughput increased immediately. The kids get more reps, and our cleaning time dropped from hours to thirty minutes a day.” — Indoor trampoline park operator, Northern Europe

“As a gymnastics academy, hygiene and predictable landings are critical. The airbag’s consistent feel and easy cleaning have made it a core part of our freestyle program.” — Gymnastics head coach, regional training center

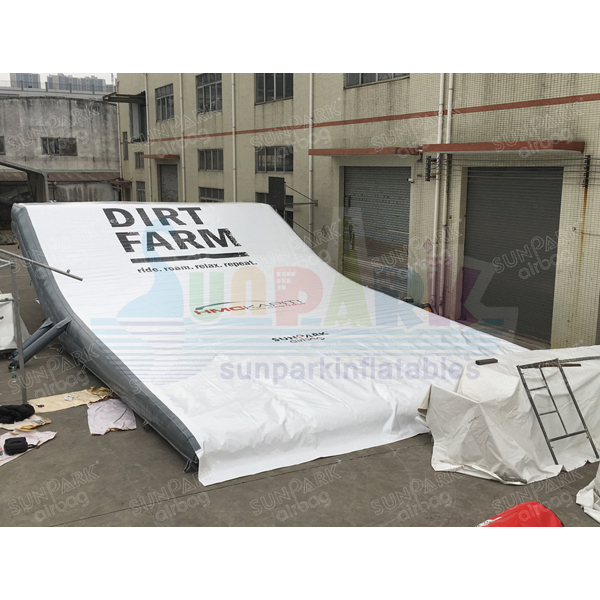

“We use the foam pit airbag for ski and snowboard training in summer. It’s durable, easy to tune, and translates very well to on-snow landings.” — Action sports coach, alpine training camp

(Anonymized quotes are typical of feedback we collect from operators — contact SunparkAirbag for full case studies and references.)

Installation, anchoring & operations checklist

If you’re considering converting to a foam pit airbag or specifying one for a new build, here are operational steps:

Measure the envelope: account for run-in, run-out and service access.

Select footprint & chamber configuration: choose pillar density and cushion depth appropriate for expected users (kids vs. adults, light vs. heavy athletes).

Power & blower planning: ensure dedicated circuits and redundancy for continuous operation.

Anchor plan: follow the manufacturer’s anchor map; add anchors for outdoor/windy sites.

Staff SOPs: daily checks, vent settings log, cleaning regime and incident reporting.

Signage & progression rules: enforce one-at-a-time entries, spotter use, and proper footwear.

For examples of hybrid installs and application notes, see Sunpark’s Foam Pit Jump Airbag and Air Landing overview.

Use cases — who benefits most from foam pit airbags?

High-throughput trampoline parks that need quick resets and easy cleaning.

Gymnastics academies focused on progressive skills and hygiene.

Action sports training centers (snowboard, ski, BMX) that want consistent landings and portability.

Stunt training / production where quick reset and high-energy hits are common. See Stunt Airbag category.

Consider pairing with related products if you run mixed programs: Trampoline Airbag for air-awareness, or Inflated Landing Bag (FMX) for heavier impacts.

Frequently asked questions

Q — Are foam pit airbags safe for young children?

A — Yes, when sized and tuned for lighter weights with staff supervision and clear progression rules.

Q — Can foam pit airbags replace foam cubes completely?

A — Many facilities use airbags as a full replacement; others prefer hybrid setups (airbag + some foam) for specific activities. See the Foam Pit Airbag product for configuration options.

Q — How often do airbags need repair?

A — Routine inspections and prompt patching of small tears will keep an airbag serviceable for years. Manufacturers provide repair kits and spare parts.

Q — Will an airbag bottom out under heavy impact?

A — Properly specified multi-pillar airbags are engineered to prevent bottoming-out even under heavier loads; request impact attenuation data from vendors.

Decision checklist — is a foam pit airbag right for you?

Ask yourself:

Do I need higher throughput and lower cleaning time? → Airbag favored

Do I have budget for ongoing foam replacement? → Airbag likely to save OPEX long-term

Do I require consistent, tunable landings for athlete progression? → Airbag favored

Is initial lower CAPEX more important than long-term cost? → Traditional foam pit may suit short-term / low-usage scenarios

If several of the first three answers are “yes,” a foam pit airbag will likely be the better investment.

How to procure — practical next steps

Contact vendors with site footprint and expected usage patterns. SunparkAirbag’s product pages provide helpful starting points: Foam Pit Airbag and the broader Products hub.

Request technical specs, anchor plans, blower recommendations and test reports.

Ask for operation & maintenance guides and case studies from similar facilities.

Get quotes for full installation including power, anchors and staff training.

Closing thoughts

Both traditional foam pits and foam pit airbags provide safe landing surfaces, but they answer different operational needs. For parks and training centers prioritizing hygiene, throughput, consistent performance and lower long-term environmental impact, a foam pit airbag is an excellent choice. For smaller, low-usage sites where CAPEX must be minimized and foam replacement is acceptable, a traditional foam pit still works.

If you’d like to explore options or get a custom quote, visit SunparkAirbag’s foam pit solutions: Foam Pit Airbag product page and the Foam Pit Jump Airbag. For complementary systems and multi-sport workflows see the Trampoline Airbag product and the Air Landing overview.